Cladding of walls and floors with porcelain, clinker, tile or ceramic tiles is one of the most difficult finishing processes. Installation of tiles requires not only accuracy and professionalism from the performer, but also knowledge of the features of the use of various building materials, primarily tile glue.

Basic requirements for tile adhesive

The usual concrete-sand mixture for laying tiles was almost completely replaced by special adhesives. This is due to a number of indisputable advantages of adhesive for ceramic tiles:

- Concrete-sand mixture is not able to ensure the durability and reliability of the masonry.

- When performing large-scale construction, the necessary proportions for preparing the working solution are not always observed.

- It is easier to work with tile glue than with concrete-sand mixture.

- The consumption of adhesives is less, since even a small layer provides sufficient adhesion of materials.

- A large assortment of glue allows you to choose the optimal composition based on the type of tile, base and conditions of use of the finish.

Before deciding which glue for the tile to choose, you need to know the basic requirements put forward before a high-quality adhesive composition:

- High adhesive properties. The glue must reliably hold plates of various weights. It is desirable that the composition quickly set and adhere to surfaces.

- The ductility of the glue is responsible for ensuring that the composition does not spread on the tile and base.

- When choosing glue for floor tiles, you need to pay attention to compositions with increased spreadability. This is necessary so that the mixture fills all available voids.

- The rate of return of water - solidification of the solution. It is important that the glue does not harden too quickly, and that it is possible to adjust the location of the plates.

Classification of tile adhesives by composition

Depending on the type of constituent components, tile adhesive is usually divided into the following groups:

- cement-based adhesives,

- epoxy adhesives

- dispersion compositions

- polyurethane adhesives.

"Cement" adhesives have an affordable cost, therefore, are popular among consumers. The composition of the adhesive includes cement, sand and polymer additives. All of these ingredients give the adhesive composition the necessary qualities: water resistance, ductility, adhesion of the plates with the base of the cladding and the presence of a deformation range. Before use, the solution must be diluted with water. The glue has a short setting period, so you need to work with it quickly enough. The elastic characteristics of the composition depend on the type and amount of polymer additives.

Epoxy adhesive Recommended for use with facing materials that have a smooth base. This is a multicomponent composition - the kit includes epoxy in liquid form and a catalyst. Before use, mix both elements according to the instructions on the packaging. Epoxy adhesive has the following advantages:

- provides reliable "coupling" of materials,

- waterproof - the glue is suitable for use in wet rooms,

- frost resistance

- epoxy does not shrink,

- the adhesive turns into a monolithic polymer and no cracks form on its surface,

- porous materials do not stain when glued.

Among the disadvantages of glue include:

- higher cost in comparison with the "cement" composition,

- when working, it is important to strictly observe the proportions of mixing the components of the adhesive,

- in the cold, glue constituents can crystallize.

Dispersion adhesive does not contain solvents, the type of composition is pasty. Dispersion adhesive for tiles - reinforced, as it has enhanced adhesion properties. This quality allows using the composition for processing non-standard materials: drywall sheets, plastic, wooden and metal surfaces, slippery walls. Purchased glue is ready for use and does not need additional preparation.

The dispersion composition is the optimal adhesive for the outer tile, which withstands the severity of volumetric elements. The disadvantage of this glue is its high cost. However, its consumption is almost two times less than other adhesive mixtures.

Polyurethane adhesive for tiles, it can be one- or two-component. The composition has the following characteristics:

- resistance to chemical compounds,

- lack of moisture absorption,

- withstands temperature fluctuations in the range from -55 ° С to + 125 ° С,

- provides additional insulation of the base,

- lack of a specific smell,

- reliable coupling of a tile with a surface of the basis.

Polyurethane compositions are classified by the method of application. Some compounds are better suited for arranging “warm” floors, while others are suitable for treating substrates subject to periodic deformation / vibration.

How to choose tile adhesive?

When choosing glue for a tile several factors are considered.

The most important are:

- The size of the finishing material. For example, for large-format tiles, special epoxy compounds should be used, and universal mixes are suitable for standard tiles.

- Type of rough base. For smooth cement, concrete, brick surfaces, standard adhesive compositions are suitable, for uneven and unstable substrates - only specialized mixtures.

- Composition. Traditional types of tile adhesive are represented by cement mixtures. This is an inexpensive, versatile product that is suitable for all types of standard tile materials. If you want to lay porcelain tiles, large-format tiles and other heavy finishes, cement-based glue can no longer cope with this task, so the choice falls on epoxy or dispersion adhesives for tiles with increased adhesive ability.

- Resistance to adverse effects. The characteristics of the tile adhesive must be selected depending on the intended operating conditions. For example, a composition resistant to moisture and condensation is required for a bathroom and a bathroom; frost-resistant mixtures are required for balconies and loggias.

Important! It is difficult to say which tile adhesive is worth choosing, because a lot will depend on the operating conditions of the laid tiles. You should refuse to buy universal cheap formulations.

Litoflex k80

Many experts consider the Litoflex K80 to be the best tile adhesive that they choose for laying work indoors and outdoors.

The composition is resistant to temperature changes, high humidity, high adhesive performance.

It is recommended to apply this adhesive for tiles with a thickness of 1-2 mm. Litoflex K80 can be used to lay porcelain stoneware and large-format tile products.

The advantages include:

- Increased ductility.

- Possibility of laying heavy finishes.

- Universality of use.

- Good adhesion with different types of rough bases.

After cooking, the finished mixture can be used for 7-8 hours. The optimal surfaces for laying with Litoflex K80 are: concrete, cement, stone, brick, plaster substrates.

The cost of one package of 25 kg is about 600-700 rubles. The price of the Litoflex K80 is its drawback.

Ceresit CM-11

The composition of the adhesive for tiles Ceresit CM-11 includes special additives that enhance the properties of the composition, which allows you to perform styling with it using inside and outside the premises.

Ceresit CM-11 is suitable for installation of heavy finishes. The prepared composition is resistant to aggressive substances. Well suited for laying porcelain products.

Important! The manufacturer does not recommend the use of Ceresit CM-11 if the tile is supposed to be laid on the surface under which the heating elements are laid ("warm floors", etc.).

The advantages of Ceresit CM-11 include:

- Low consumption (in comparison with analogues).

- The ability to withstand loads of up to 40-50 kg per m2.

- Quick hardening of the applied composition.

The cost of packing 25 kg is 250-300 rubles.

Knauf fliesen

Knauf Fliesen is included in almost all tile adhesive ratings, because it is really high-quality, good and inexpensive products that are great for working in bathrooms, as well as for laying outdoors.

The mixture is characterized by increased ductility, a long service life, which is ensured by the presence of artificial additives in the composition.

Important! Glue for Knauf Fliesen tiles is able to tolerate minus temperatures up to -30, -35 degrees, so it is suitable for tiling with attics, balconies, arbors, etc.

The packaging cost of 25 kg is about 300-350 rubles.

The benefits of Knauf Fliesen include:

- High level of adhesion of the composition after application.

- Possibility of applying a thin layer for laying heavy and large-format tile products.

- Guaranteed high European product quality.

- The mixture does not spread immediately after application.

What glues cement glue

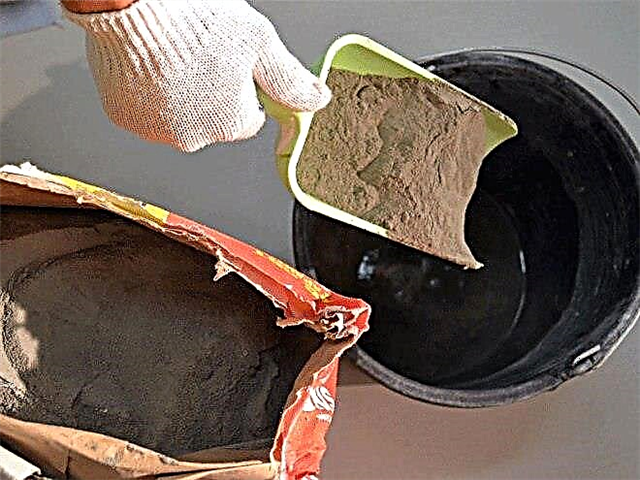

Cement tile adhesive is a dry mixture of white or gray cement, sand and polymer additives. To prepare the glue, the mixture must be mixed with water in a bucket with a mixer. The tile must be put in time for 20-30 minutes, until the mixture has dried.

For laying ceramic tiles and porcelain stoneware, gray glue is used, for laying mosaics and natural stone - white.

For facade work, it is recommended to choose elastic reinforced adhesive with polymer additives. Such glue is not afraid of moisture, high and low temperatures and holds tiles well on concrete, cement and cement screed.

What is convenient dispersion glue

Dispersion adhesive for tiles is a ready-to-use adhesive with a creamy or semi-liquid consistency. Ready-made glue is convenient for working indoors, where it is undesirable to dust, kneading the solution.

Dispersion glue is intended for any ceramic tile, clinker and natural stone. The glue is white, so you can lay mosaics and tiles for kitchen aprons with it.

The glue adheres confidently to cement screed, concrete, gypsum board, gypsum plaster, silicate brick, old tile, rigid foam and old paint. Dispersion glue hardens within 40 minutes. If glue remains after finishing work, it can be stored in a jar with a tightly closed lid.

Dispersion glue should not be used during outdoor work, as it does not withstand negative temperatures. Dispersion glue costs about 10 times more expensive than cement glue.

What are the features of reactive glue

Reactive tile adhesive consists of two components - an epoxy or polyurethane base and an organic catalyst. To prepare the glue, these two components must be mixed. After mixing, the glue immediately begins to harden, so you need to work quickly.

Epoxy reactive glue is heavy-duty, waterproof, frost-resistant, does not shrink and does not crack with time. It can be used in any operating conditions on the street and indoors. Epoxy glue is recommended for facing smooth surfaces: metal, plastic, wood, drywall, facing stone or brick.

Polyurethane adhesive is very flexible, moisture resistant, not afraid of high and low temperatures. The glue adheres well to any substrate, including metal, wood, plastic, bitumen and waterproofing. It is used when laying tiles on the facades of houses, in pools and for gluing large plates of natural stone.

Reactive glue is very expensive - about 20 times more expensive than cement.

What are adhesion classes

Tile glue is divided into two adhesion classes - 1st, or 2.1th class - this is the base glue for lightweight ceramic tiles up to 450 × 450 mm in size, which is glued to a flat surface inside a heated room.

2nd class - reinforced, it is used for laying large-format tiles on walls and floors, including with heating. Such glue can be used to fix the tile on the old tile and paint.

In Russia, you can often find an indicator of the degree of adhesion in units of MPa. If the adhesive has an adhesion of more than 0.5, but less than 1 MPa, it can be attributed to the 1st class of adhesion. Adhesive with adhesion above 1 MPa belongs to the 2nd class.

What does adhesive curing speed mean?

Hardening speed - this is the time after laying, after which the glue finally hardens. Usually this is 24 hours, after the same time you can overwrite the seams.

If you need to lay tiles in the bathroom of the living room, it is recommended to choose a quick-hardening adhesive. In this case, you can walk on the tile after three to four hours. Quick-hardening adhesives are marked with the Latin letter F.

The curing speed of the glue is important when laying natural marble, because under the influence of moisture, marble can change its color.

What does open layer time and adjustment time mean?

The time of the open layer is the period after which the adhesive applied to the surface begins to become covered with a film and lose its adhesive properties. Most adhesives have an open layer time of 10–20 minutes.

Tile adjustment time is the time after which the position of the tile already laid on the surface can be changed. It is about 30 minutes.

Glue with a long open-layer time does not dry out for 30-60 minutes. It is marked with the Latin letter E. Such glue can be applied immediately to the entire wall, and then start laying tiles. Glue with this marking also takes longer to adjust the tiles than conventional glues - up to 60 minutes. An adhesive with a long adjustment time is recommended for beginners.

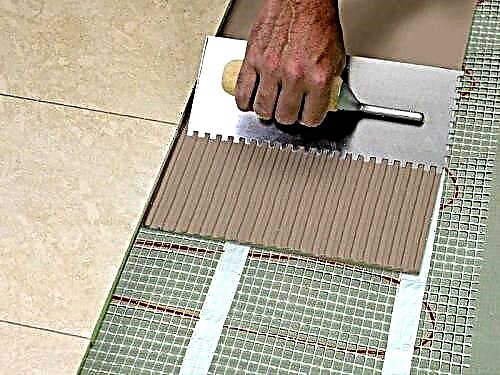

How to apply glue

It is convenient to apply tile adhesive with a rectangular notched trowel with a smooth back. First, the surface is puttied with a smooth side, after which a glue layer of the desired thickness is formed with the serrated side. The maximum thickness of the glue layer does not exceed 1 cm. There are thick-layer compositions for the simultaneous leveling of the floor and laying of tiles. The thickness of the layer of such glue should not exceed 3 cm.

When working indoors, glue can be applied both to the base of the wall or floor, and directly to the surface of the tile. During street work - both on the base and on the tile so that voids do not form under the cladding.

Varieties of adhesive mixtures by method of application

According to the international classification, adhesive for laying tiles is divided into 5 main categories:

- The adhesive composition for internal work belongs to the category of the most budgetary. Shows sufficient adhesive characteristics when fixing ceramic tiles to brick / concrete substrates. The composition is limited by the number of special additives, so this glue is not recommended for outdoor use. Under the influence of high humidity and temperature extremes, the performance of the adhesive deteriorates.

- Glue of the increased fixing - the best glue for a tile of large sizes and a natural stone. Such glue is able to withstand high tensile loads and has increased adhesion. These qualities allow you to use the mixture in conditions of non-standard temperature and dynamic effects. Before applying strong fixation glue, the old surface can not be cleaned (do not remove the previous lining if it is firmly held on the base).

- Universal type glue - the most popular among tilers. Suitable for outdoor use and indoor decoration. However, experts note that such an adhesive may not be reliable in conditions of high humidity and temperature extremes. In addition, for plates measuring 30 * 30 cm and more, it is better to choose a different adhesive mixture.

- Moisture-resistant composition - specially designed glue for bathroom tiles and steps. The glue contains a hydrophobic modifier, which allows it to be used when laying tiles in the pool and fountains.

- The adhesive for fixing the floor tiles has a plasticizer, which allows you to qualitatively fill the troughs and voids of the base. The ability to “glue” the glue makes it impossible to use it on vertical surfaces. According to other criteria, the adhesive is comparable to universal.

In addition to these adhesives, there are specialized compounds: heat-resistant for facing stoves and fireplaces, frost-resistant for outdoor work in harsh climatic conditions

Dry and ready mixes: advantages and disadvantages

You can buy glue for tiles in finished form (in buckets) or in the form of a dry composition (in bags) for cooking. What is their difference and which mixture to choose?

Dry mixes are based on cement. The main advantage of this glue is that it can be laid on uneven walls that have different curvature differences. Glue, in addition to the main purpose, serves as a leveling layer.

An essential plus of dry glue is affordable cost. With the same amount of self-prepared mixture and purchased glue, the price of the first option will be an order of magnitude lower.

For the application of ready-made mixtures (on a polyurethane basis), a smooth base is required. However, such a composition is more durable and reliable than cement-based glue.

Tile Adhesive Criteria

In order not to be mistaken with the choice of glue, it is necessary to compare the characteristics of the adhesive composition, the type of facing surface and the operating conditions of the finish. Here are the main criteria for choosing tile adhesive:

- Tile operating conditions. For the kitchen, the corridor, standard glue for tiles is suitable - the mixture is universal, designed to fix the plates on the walls. In the bathroom you need to use moisture resistant glue. However, it is possible to save and lay the lining on universal glue, and grout between the tiles with a moisture-proof mixture.

- Type of cladding. When buying glue, it is necessary to take into account the level of adhesion of the composition to various surfaces. Dry cement mixes are not suitable for facing a wooden base, OSB floor. All types of surfaces are usually divided into simple and complex. Simple bases include: concrete, brick, cement and sand screed. Complex surfaces for facing: drywall, metal, glass, plastic, as well as substrates that are deformed or subject to periodic vibrations. For finishing simple substrates, glue with a low level of adhesion is suitable - up to 0.5 MPa. The fastening of plates to complex surfaces must be performed with an adhesive composition with an adhesion coefficient of at least 1 MPa.

- Weight and dimensions of the plates. This criterion is especially relevant when choosing glue for finishing vertical surfaces. It is important to remember the basic rule: the larger the tile, the greater the strength of the adhesive composition.

Overview of tile adhesive manufacturers: specifications and prices

The same types of glue from different manufacturers may vary in composition. When buying tile glue, it is advisable to choose the products of popular, trusted companies. In the construction market, the following mixes for masonry have worked well.

Ceresit CM-11 - dry cement mixture with additives of polymers and mineral fillers that increase adhesion. The main purpose is the installation of faience facing and ceramic tiles with sizes from 50x50 mm to 400x400 mm on undeformed bases. The cost of one bag (25 kg) is about 200 rubles. Specifications:

- glue consumption - 2-7 kg / m2,

- base temperature - not less than + 5 ° С,

- drying time - 1 day,

- the shelf life of the prepared mixture is 60 minutes.

Ceresit CM-17 - elastic tile adhesive used for cladding various types of surfaces outside and inside buildings. Application area:

- lining of tanks and pools,

- furnish furnaces and fireplaces, provided that their surface does not heat above 80 ° C,

- facing glazed surfaces, including without removing the old coating,

- laying tiles on the terrace, balcony, operated roof, basement, etc.,

- arrangement of heated floors.

Ceresit CM-17 is not a cheap tile adhesive (price for 25 kg - about 800 rubles).

Moment - A budget option for laying ceramic tiles. Designed for tiling with dimensions of not more than 30x30 mm and water absorption above 3%. Suitable for cement-lime, concrete, brick and cement-sand substrates.

Important! If Moment glue is used for facade decoration, then a special emulsion must be added to it

Characteristics of glue Moment:

- base temperature - from + 5 ° С to + 30 ° С,

- the temperature in the room during work is about 20 ° C, humidity is not more than 60%,

- adjustment time - 10 minutes,

- glue cost - 125 rubles / 25 kg.

Litokol Litoflex K80 - elastic highly adhesive glue with an extended period of the open layer for fixing porcelain stoneware. The basis of the dry adhesive mixture is Portland cement, inert fillers and organic additives. This is a universal adhesive designed for exterior / interior, wall / floor cladding. Suitable for fixing porcelain stoneware, ceramic tiles, natural stone and clinker to stable and subject to deformation / vibration of the base.

The consumption of adhesive for tiles depends on the state of the surface and is 2.5-5 kg / m2, the cost of the dry mix (25 kg) is 1700 rubles.

Keralastic (made in Italy) - two-component polyurethane adhesive for laying stone and ceramic tiles. The composition is resistant to slipping and has a wide scope:

- installation of ceramic tiles, mosaics and stone slabs on top of plasters, screeds, metal, PVC, wood, reinforced polyester, gypsum board, etc., work is carried out both outdoors and indoors,

- laying plates on balconies, terraces, open flat roofs,

- fixation of roofing marble, slate and composite materials subject to swelling under the influence of moisture, shear, deformation and vibration.

Keralastic is great for cladding vertical surfaces and is able to hold large slabs. The cost of glue is 2800-3000 rubles / 5kg.

Lux Plus - dry adhesive composition of increased strength. The glue is used when performing finishing works inside and outside the room for facing the floor, walls with different materials: artificial / natural stone, mosaic, marble, transparent or thin tiles. The main purpose - laying tiles in the bathroom, saunas, saunas and pools. The composition is recommended for use in places with high separation loads. The price of glue (25 kg) is about 260-300 rubles.

Features and Benefits

Creps company produces compositions for various types of materials, in particular for ceramics, stone, porcelain stoneware. Among the products there is glue Kreps Reinforced. The latter has features that allow it to be used when other formulations are contraindicated.

What is the difference between Kreps with the label Reinforced:

- When finishing, there is no slipping from the walls.

- Used for the outside of fireplaces.

- It freezes quickly.

- Economically consumed.

- Suitable for underfloor heating.

- It has increased strength.

- It adheres well to a number of materials.

Grapes from Craps is a dry composition. Consists of sand, cement, plasticizers, modifying additives. The particle size is 0.63 mm.

Preparation is carried out by mixing with a liquid in a predetermined proportion. With proper preparation, a viscous mixture is obtained with a strength of M 75, adhesion - 1 MPa, resistance to frost - 35 cycles.

Parameters of adhesive labeled Reinforced far above standard compounds. The latter is well applied for standard ceramic cladding. The reinforced composition allows you to extend the working time up to 20 minutes, during which you can adjust the position of the plates. What is important for this composition is the minimum creep - not more than 5 mm.

Reference! Reinforced Kreps withstands a wider temperature range, which makes it possible to use it outside and for working with a warm floor. You can buy glue in packages of 5 and 25 kg.

Advantages of the adhesive include:

- Frost resistance - the composition withstands low and relatively high temperatures. The mixture can be safely used for fireplaces, as well as for outdoor cladding.

- Application for front buildings.

- The minimum consumption of material.

- Application at a temperature of +5.

- Increased moisture resistance. The glue will dry normally even with a high humidity indicator. He is not afraid of vapors and liquids. Therefore, it can be used for bathrooms with floor and wall cladding.

Considering the disadvantages of the tool, it should be noted that when working with it, you must strictly follow the instructions, the minimum experience with such mixtures is important. If there are no skills, it is better to contact the master, otherwise the result may not please.

It is necessary to control the amount of the mixture used, the uniformity of application, the thickness of the layer. This is especially true for laying large tiles. With insufficient adhesive, the lining may disappear over time.

Reference! Improved composition can be used for finishing in conditions with a high humidity index.

Some Kreps products include antifreeze and refractory components, which increases the useful life, strength and overall properties.

Specifications

Glue Kreps Reinforced for tiles in bags of 5 and 25 kg has the following parameters:

- The approximate consumption of the finished mixture is up to 4 kg per square meter.

- Proportion of cooking - 25 kg need up to 6.5 liters of liquid.

- The time for which you need to have time to finish - 20 minutes.

- The time for which it is permissible to correct the position is 20 minutes.

- The pot life of the glue after kneading is 4 hours.

- Application under conditions from 0 degrees.

- Sliding - maximum 0.5 mm.

- Grouting and base load - after 24 hours (for the floor –72 hours).

Application area

Reinforced Corsage is made for decoration with ceramic tiles, stone, granite. It is well suited for heated coatings inside and outside the yard.

Reinforced composition is suitable for the following coatings:

- Cement, plaster.

- Concrete, reinforced concrete (aged, dry).

- Drywall.

- Aerated concrete.

Laying with Craps can be carried out on vertical and horizontal bases, also to a small height - parapets, stair friezes, basement.

Reference! Sometimes additional fixation is required, as is the case with large tiles from 600x600 at a height of more than 1 meter.

Types of Adhesive Reinforced

Advanced Craps comes in several varieties:

- Reinforced glue. It is good to apply for heavy facing. It features increased adhesion to tiles and substrates.

- Reinforced Express. It features the fastest solidification. Contains drying accelerating additives. You can load the surface in a few hours (4-5).

- White. It has typical characteristics of Enhanced Characteristics, but additionally contains dyes that give the composition a white color. Used for glass, tile, mosaic on the walls and floor.

- Kreps Super. It has increased adhesion to mineral, glass, metal, wooden surfaces.

Kneading and storage of glue Creps

To prepare the glue, you need to take 6 liters of liquid per 25 kg of crepes glue. Mixing is carried out with hand tools or with a mixer at low speeds. The mixture should stand for 10 minutes, after which it is mixed again. The viability of the finished composition is maintained for 4 hours.

The product is stored in its original packaging for 12 months in a dry place on a stand.

Application

Before starting work, you need to prepare osonation. It should be smooth, not subject to deformation changes. Previously, the surface is cleaned of dirt, dust, grease, old compounds. It is important to degrease using special products containing alcohol.

Reference! For better grip, it is also recommended that a primer with a Kreps Primer be used. Bases that strongly absorb moisture must be treated twice.

The glue is applied to the base, then leveled with a trowel with teeth. The tile needs to be laid in 20 minutes, after this period the glue becomes unusable. Full hardening occurs during the day, after which the surface can be loaded.

After completion of work, all instruments can be washed with water. However, it should be noted that this liquid cannot be used to prepare a new portion of glue.

When working with glue, you need to use protective equipment, preventing the glue from getting on the skin and respiratory tract. If the composition nevertheless gets on unprotected parts of the body, you need to rinse them under running water.

Useful Tips

For high-quality work with glue, you need to follow the advice of professionals:

- After the main stage of work, you need to wait at least 48 hours, as for the walls, but for the floor you have to wait 72 hours, until the composition completely hardens, it is highly recommended not to load the surface earlier and start grouting.

- The larger the size of the tile, the larger the size of the trowel teeth for alignment. For example, for a 15x15 cladding, a length of 6 mm is suitable, and for a 30x30 material, 8 mm is already needed.

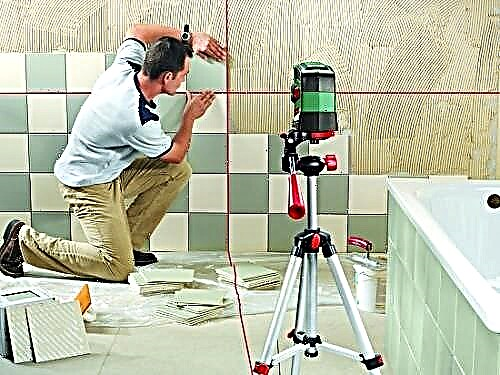

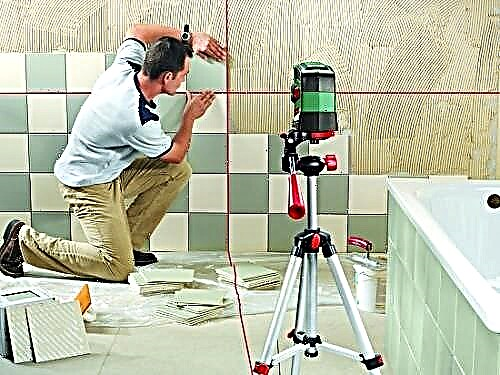

- During the application of glue, it is necessary to monitor the thickness of the layer. The optimum size will be up to 4 mm. When the lining is more than 30x30, the layer should be larger - 7 mm. When finishing the floor, you can make the layer even thicker - 9 mm. However, in any case, the material should be applied evenly over the entire surface. For convenience, a level is applied.

- When working with glue, be sure to follow safety precautions. It is important to use protective equipment in the form of gloves and a mask. Sleeves should be long so that there are no exposed skin.

Do not work at sub-zero temperatures. The optimal indicator would be +5 degrees, but you can start from zero. It is best to use a notched trowel for application, so as not to further level the surface with other tools. The base on which the product is applied must be smooth and not subject to deformation, as well as shrinkage.

Do not step on the floor immediately after finishing. You need to wait a certain time for the glue to completely dry. During the drying process, the surface must not be washed, that is, contact with liquids and mechanical factors must be excluded.

Reference! It is necessary to fix the tile as soon as possible after applying the product, without waiting for the moment when several minutes remain until the adhesive is unusable.

Reviews

Clay Creps with the label Strengthened has long been popular among professionals and amateurs. He receives many positive reviews in which the usability of the composition and its quality are noted. What is especially good is the low level of glue sliding from the walls, which is inherent in many glue mixtures. It can be used without problems even for heavy facing material.

Than Reinforced adhesive is better than standard:

- Conventional products do not have sufficient parameters for further use of the surface in extreme conditions.

- Glue with average moisture and frost resistance deteriorates much faster, and it is also subject to deformation changes.

- When using standard adhesive for floor heating, cracks appear after a couple of heating cycles, the tile is subject to expansion under the influence of high temperature. If you use special glue, this problem does not arise.

Reference! Special compounds to everything else also contain refractory and many other additives that make them significantly better. Conventional glue can not withstand conditions that will be familiar for a reinforced composition.

It will also be important that they speak well already about the operation of the finished coating. Craps does its job even under conditions of constant high humidity.

“I changed the tiles in the bathroom twice, but because I used ordinary tile glue. It is good that the next time I bought the product, I came across a consultant who explained why it is better to choose a special adhesive. Having received important information, I bought Kreps Reinforced, with which for many years not a single tile has suffered.

The combination of quality and value is another point that does not go unnoticed. Clay Creps can easily be found on shelves of construction stores in bags of 5 and 25 kg.

Glims white fix

Glue Glims White Fix is also included in the TOP of the best compositions for laying tiles.

This is a great option for the installation of decorative tile materials.

The mixture is presented in white, has high adhesion characteristics.

Important! Glims White Fix will be the best solution for decorating swimming pools, facade elements of structures, bathrooms, and bathrooms. It is often used for laying mosaics.

Glims White Fix is suitable for laying on all types of rough surfaces: wood, brick, concrete, drywall.

The cost of packaging 25 kg - 600 rubles.

Product advantages are:

- Simplicity and speed of preparation of the adhesive.

- No need to use grout after laying.

- The increased water resistance.

- High degree of plasticity of the finished mixture.

Volma Ceramics

Glue "Wave Ceramics" is used for laying tiles of medium and small format.

It is not recommended to lay tile products of complex shape and heavy materials using Wave Ceramics.

This is a Russian-made product, sold at a reasonable price - 50 rubles for a five-kilogram package.

Important! Glue "Wave Ceramics" can be used for laying medium and small size porcelain tiles on the floor.

The advantages of Wave Ceramics are:

- Affordable cost.

- Good adhesion.

- Possibility of use with any decorative not heavy finish.

- High elasticity characteristics of the finished composition.

- Quick setting of the mixture after application to the wall.

Prospectors Standard

Inexpensive products from a Russian company. Suitable for performing traditional tile laying in the house.

Suitable work surfaces: plastered, brick, concrete, stone.

Important! It is not recommended to use Standard Prospectors glue if laying heavy ceramic finish is required.

The advantages of the "Prospectors Standard" include:

- High degree of ductility.

- The possibility of using the prepared mixture for 3-4 hours.

- Good adhesion characteristics that do not lose over time.

- Resistance to moisture.

The cost of packing 25 kg is about 200 rubles.

On the video: Glue for tiles - manufacturers comparison.

Bergauf keramik

Democratic in price, high-quality adhesive for tiles, characterized by increased ductility.

The optimal solution for laying tiled products indoors.

Important! The composition of Bergauf Keramik is suitable for installing tiles in bathrooms, hallways, closed balconies, bathrooms, because the finished mixture has high moisture resistance.

If you need to lay heavy and large-format tile materials, then with the help of Bergauf Keramik they can only be mounted on the floor, which is indicated on the product packaging.

The cost of packing 25 kg is about 300 rubles.

The advantages of Bergauf Keramik are:

- High level of elasticity of the prepared mixture.

- Quick setting of the mortar immediately after application to the surface.

- Low cost.

- Universality of use.

Eunice 2000

Specialized adhesive with the highest adhesion. Therefore, it can be used for wall decoration inside and outside buildings, natural and artificial stone, large-format and heavy tiled materials, porcelain stoneware, etc.

For example, Eunice 2000 can withstand the load of a 600x600 mm porcelain tile.

Important! The manufacturer does not recommend the use of Eunice 2000 if it is planned to lay the tiles on a surface with laid heating elements (“warm floors”), as well as on the basement surfaces of buildings.

The cost of packing 25 kg is about 200 rubles.

Advantages of Unis 2000 glue are:

- Long term of operation.

- High-quality retention of the laid tiles.

- High degree of ductility.

- Reasonable cost.

Keraflex maxi

Choosing which glue is best suited to adhere ceramics and ceramic tiles, many experts stop at Keraflex Maxi. This is a high-quality, highly plastic composition that can be used in the domestic and professional fields.

Keraflex Maxi glue is used for tiling of internal premises, building facades, laying of tiles in car washes and garages, installation of decorative plates from various materials.

Keraflex Maxi contains special additives that increase the adhesive characteristics of the prepared mixture, extend the life of the product, and improve adhesion.

The only drawback of Keraflex Maxi tile adhesive is its cost - about 1000-1200 rubles per package.

The advantages of the product include:

- The ability to adjust the position of the tile products for a long time after installation.

- Lack of sliding of the stacked products after fastening.

- The maximum level of resistance to moisture, oil compounds, solvents, aggressive chemicals.

- High adhesion to various types of rough surfaces.

Bolars Wall Fix Keramik

Glue for tiles with increased ductility, which is designed for laying small tiled products and mosaic materials indoors.

After fixing the finish, consumers have another 20-30 minutes to adjust the position of the mounted product.

The products are environmentally friendly, they are sold already prepared in 3 kg Vedas. The cost of one bucket is quite high - about 1000 rubles.

The advantages of Bolars Wall Fix Keramik include:

- The optimal solution for gluing tiles to complex and heterogeneous substrates.

- Possibility of use for laying tile finish on "warm floors".

- Relatively low consumption.

Conclusion

As already noted at the beginning of the article, it is difficult to choose the really best glue for the tile, because a lot will depend on the type of stacked products, type of rough surface, features of operation and other factors.

Particular attention should be paid to inexpensive tile adhesives from well-known manufacturers: Ceresit, Knauf, Litoflex, Volma, Prospectors.